Production Capacity and Equipment

Vyborg Shipyard PJSC is located in the town of Vyborg, Leningrad region, on the coast of the Hovenlahti bay, a part of Vyborg Bay, at a distance of 18 km from the open sea. The territory of Vyborg Shipyard occupies an area of 44.18 hectares. Vyborg Shipyard water area of 135 thousand m² is on the company balance sheet.

The total construction area of the shipyard is 17,8 hectares, including:

- production area - 82,5 thousand m²

- covered - 64,0 thousand m²

- open - 18,5 thousand m².

Vyborg Shipyard is located on the motorway Vyborg-Primorsk and is 10 km from the international Scandinavia motorway. There are two railway lines leading to VSY territory. Vyborg Shipyard is limited on the north-west by Vyborg Port area that enables to receive goods delivered by sea.

Primary and secondary production workshops on the territory of the shipyard are located in blocks by type of production:

- assembly and welding;

- hull assembly;

- outfitting;

- mechanical treatment;

- insulation and painting works.

Steel primary treatment floor

Steel primary treatment floor (shot-blasting and priming) has automated line Rősler for treating steel plates with maximum size 3200x12000 mm at thickness 3 mm and profiles H up to 500 mm, L up to 12000mm. Taking into account carrying capacity of the crane for lifting plates at feed stations of gas-cutting lines with increasing the thickness of plates dimensions will be reduced (for b = 50 mm the plate size will be 3.2 m x 5 m). The line was put into operation in 2009.

Steel primary treatment floor capacity - 40 000 tons per year.

Steel cutting floor

There are 6 machines for gas and plasma cutting of plates:

- 2 off – with operating area 3,2 х 16m,

- 1 off – with operating area 2,5 х 8 m,

- 2 off – with operating area 2,5 х 10m.

- a machine for gas and plasma cutting Messer with swivel block for plasma beveling, sizes of operating area – 2 х 3,2 х 12м. Year of commissioning – 2013.

Production capacity of machines for cutting the details from plates – 24 000 tons per year.

Automated profile cutting line (laser) PCL600Н by HGG. Production capacity of the line – 6000 tons per year. Year of commissioning – 2013.

Totally steel cutting floor provides 30 000 tons per year.

Steel bending floor

The equipment of steel bending floor provides bending of details from plates with thickness up to 70-80 mm.

Under the program for construction of icebreakers project 21900 M there was put into operation the bending press VPF-1000 with force 1000 tons intended mainly for bending the outer shell details from steel plates. The press is served by 2 semi-gantry cranes. The press enables to bend details from steel plates with thickness of 50 mm or thicker. Year of commissioning – 2012.

Section assembly & welding floor

Section assembly & welding floor (Block «К») provides assembly of sections in the shop, weight of sections - from 30 to 60t, in volume - about 15 000 tons.

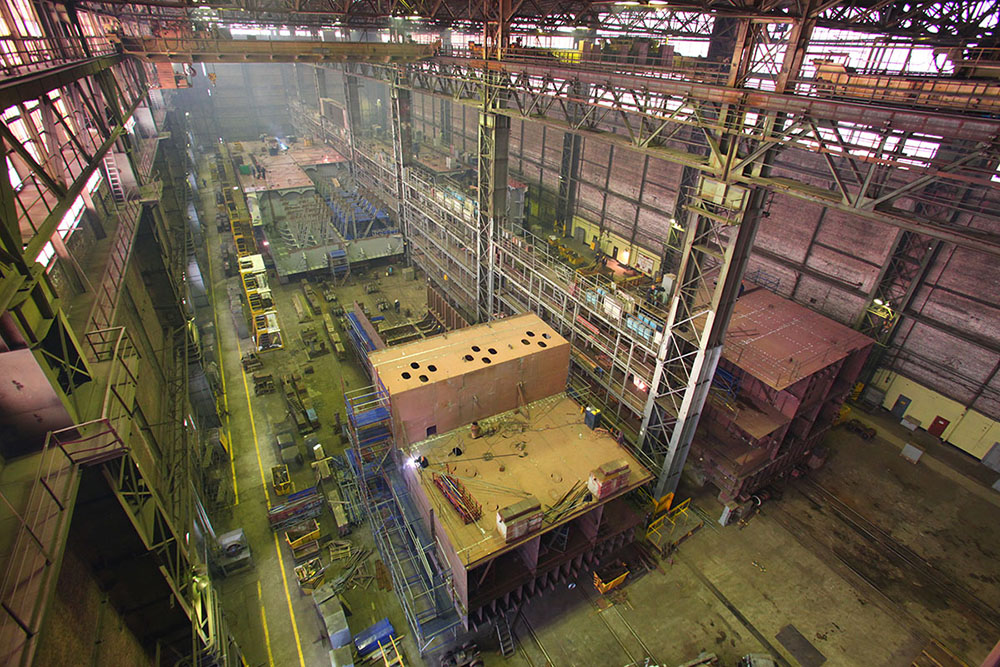

Hull assembly shop

Hull assembly shop includes two blocks «Б» and «Э». Total production capacity of section assembly in these blocks is 20 600 tons. The shop enables to assemble hull blocks with weight up to 300 tons. In blocks "B" and "E" on each line there are two cranes with capacity 50t. The block "Э" can be used for assembling blocks L x B x H 21x25x15m with weight up to 300 tons. In block "Э" there can be erected the vessel’s hull with the following dimensions: length - from 136.5 to 151.5 m, beam - 18.0 m and height - 21,0 m.

Hull assembly shop includes two blocks «Б» and «Э». Total production capacity of section assembly in these blocks is 20 600 tons. The shop enables to assemble hull blocks with weight up to 300 tons. In blocks "B" and "E" on each line there are two cranes with capacity 50t. The block "Э" can be used for assembling blocks L x B x H 21x25x15m with weight up to 300 tons. In block "Э" there can be erected the vessel’s hull with the following dimensions: length - from 136.5 to 151.5 m, beam - 18.0 m and height - 21,0 m.

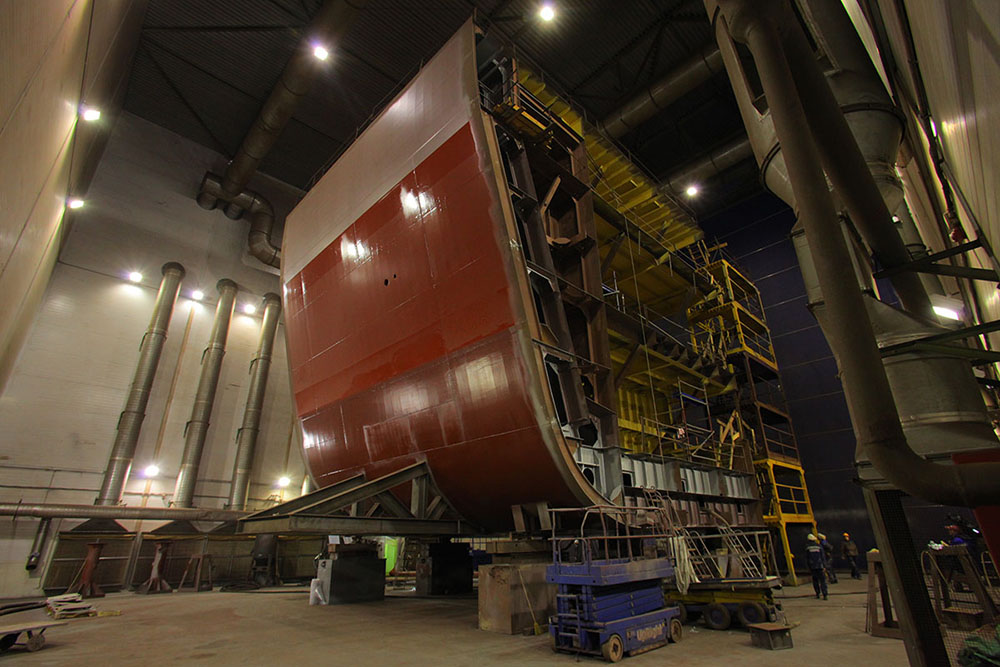

Shot-blasting and painting cells

Hull sections and blocks are shot blasted and painted in several painting cells. The most up-to-date are shot-blasting and painting cells for preassembled hull blocks. Sizes of treated and painted blocks - L x B x H = 24 х 22 х 15m, weight - up to 300t. Year of commissioning – 2010.

Total production capacity of all painting cells of the shipyard is about 400 000 m2.

Open building berth

At open building berth there are cranes with capacity 32t enabling to install masts, funnels and other structures not installed in covered-in building berth. Lifting height of the cranes is 29,5m.

Floating-out basin

The floating-out basin provides launching of vessels with length up to 139,0 m, beam up to 18,0 m and draught 4,6 m. Moving the vessel from covered-in building berth to open building berth and then to floating-out basin is carried out by a train consisting of trolleys and beams. Max. weight during transportation shall not exceed 4800 t.

For construction of vessels with dimensions exceeding the above there is used a semi- submersible barge «Atlant».

Main characteristics of the barge:

- Length 130m;

- Beam 35m;

- Depth 7,3m;

- Freeboard from deck line 2,4m;

- Draught 5,3 m;

- Deadweight 14 419t;

- Gross tonnage 11 502t.

Outfitting quays

For assembly of big-size floating facilities and final fitting-out of the vessels afloat at the shipyard there are used two outfitting quays:

- outfitting quay with piers 14, 15 and 16. Length – 300m, width – 30 m, depth at the cordon – 8,0 m. At the outfitting quay there are two cranes with capacity 10t each.

- outfitting quay with piers 19 and 20. Length – 250m, width – up to 35 m, depth at the cordon – 9,5 m. At the outfitting quay there are two gantry cranes with capacity 100t each, lifting height – 50m, capacity 100t at outreach up to 30m, capacity 50 t at outreach up to 50m from crane axis.

Pipe & mechanical fitting shop

Pipe & mechanical fitting shop has the equipment providing cold bending of pipes with diameter up to 133 mm and machines for hot bending of pipes with diameter up to 426 mm. Maximum production capacity – 720 tons per year.

Captain’s service

Captain’s service has a floating crane «Bogatyr-6» used for assembly of big-size floating facilities and final outfitting of the vessels after launching. Maximum crane capacity 300t at outreach 26,7 m and lifting height from water level – 40,1 m.